Logistics Hubs for Sale Comprehensive Guide, Benefits, and Real-World Use Cases

Logistics hubs for sale are strategically located facilities designed to handle storage, distribution, and transportation functions within a supply chain. Unlike standard warehouses, logistics hubs serve as centralized nodes that connect manufacturers, suppliers, and consumers. Purchasing a logistics hub offers businesses or investors long-term control over vital supply chain assets, making them essential in industries where efficiency and scalability are key.

The demand for logistics hubs is rising due to the growth of global trade, the rapid expansion of e-commerce, and the increasing need for efficient last-mile delivery. Businesses view logistics hubs not only as real estate investments but also as operational assets that support faster order fulfillment, cost reduction, and market expansion.

Importance of Logistics Hubs in Supply Chains

Logistics hubs are the backbone of modern supply chains. They provide centralized locations where goods are received, sorted, processed, and distributed to their final destinations. This system ensures businesses can meet consumer demand quickly and efficiently, whether serving retail outlets, wholesalers, or direct-to-consumer deliveries.

Owning logistics hubs enhances supply chain visibility and control. By strategically positioning hubs near highways, airports, seaports, or major urban centers, companies can minimize transportation costs and reduce delivery times. This strategic advantage directly influences competitiveness in industries where speed and reliability are critical.

Benefits of Investing in Logistics Hubs

One of the main benefits of logistics hubs for sale is long-term cost savings. By owning rather than renting, businesses eliminate recurring rental costs and build equity in a valuable asset. Ownership also provides more freedom in customizing the facility to specific operational needs, whether adding automation systems or expanding storage capacity.

Another significant benefit is supply chain resilience. With a dedicated logistics hub, businesses can reduce dependency on third-party providers, maintain greater control over inventory management, and respond more effectively to market disruptions. Additionally, logistics hubs often appreciate in value over time, making them attractive as both functional assets and investment properties.

Real-World Examples of Logistics Hubs

1. DHL Global Forwarding Hubs

DHL operates advanced logistics hubs across Europe, Asia, and North America. These hubs are designed for seamless integration with air and sea freight networks, ensuring global connectivity.

Their relevance lies in international scalability. By owning and developing logistics hubs near major airports and ports, DHL reduces transit times and improves service reliability. These facilities also incorporate advanced technologies like automated sorting and AI-driven tracking systems to enhance efficiency.

2. UPS Worldport in Louisville, Kentucky

UPS’s Worldport hub in Kentucky is one of the largest logistics hubs globally. It handles over a million packages daily and is fully integrated with global air cargo operations.

The relevance of this hub is in speed and capacity. By investing in such a massive facility, UPS ensures rapid package movement across continents, supporting its reputation for reliable global delivery. The hub also demonstrates how logistics real estate can serve as a cornerstone for long-term business growth.

3. Singapore’s Changi Airfreight Centre

Changi Airfreight Centre in Singapore is a logistics hub that combines air cargo handling with warehousing and distribution facilities. Its location within one of the world’s busiest airports makes it a strategic asset for Asia-Pacific trade.

The relevance of this hub lies in regional connectivity. Businesses using the facility gain direct access to one of the fastest-growing markets in the world. The hub also highlights how owning logistics real estate in high-demand regions creates unmatched competitive advantages.

4. Amazon Fulfillment Network Hubs

Amazon owns and operates a global network of logistics hubs that serve as fulfillment centers. These hubs are strategically located near major metropolitan areas to enable fast last-mile delivery.

The relevance of Amazon’s logistics hubs is in customer experience optimization. By owning these properties, Amazon ensures control over its supply chain, reduces reliance on third parties, and sets industry standards for delivery speed. The integration of robotics and AI also illustrates how modern logistics hubs evolve with technology.

Use Cases of Logistics Hubs for Businesses

For large retailers, logistics hubs solve the challenge of managing thousands of SKUs across multiple markets. By owning centralized hubs, companies can ensure product availability and reduce stockouts.

For manufacturers, logistics hubs streamline the movement of raw materials and finished goods. They reduce the risk of bottlenecks by serving as staging points that balance production and demand.

E-commerce businesses particularly benefit from logistics hubs by reducing delivery times. As consumer expectations shift toward same-day or next-day shipping, owning hubs near urban centers ensures businesses can compete effectively in crowded markets.

How Technology Enhances Logistics Hubs

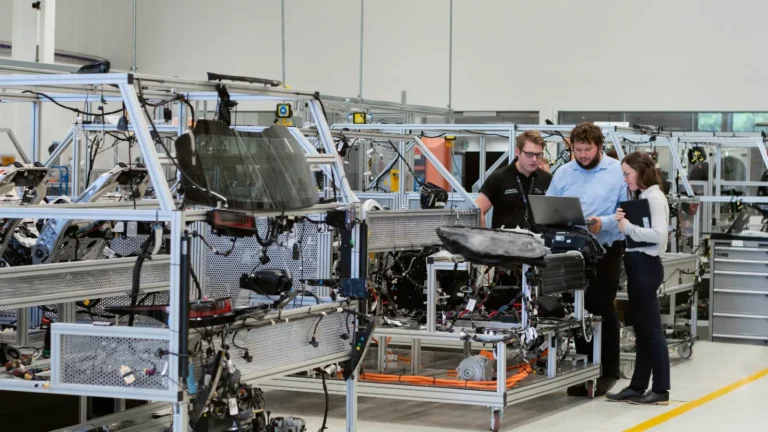

Technology has become central to the evolution of logistics hubs. Advanced warehouse management systems (WMS) provide real-time tracking of goods, improving visibility and reducing errors. IoT sensors monitor conditions such as temperature and humidity, ensuring product integrity for sensitive items like pharmaceuticals and food.

Automation and robotics play a major role in boosting efficiency. Automated guided vehicles (AGVs) and robotic arms speed up order picking and reduce dependency on manual labor. Artificial intelligence further enhances hubs by enabling predictive analytics that optimize inventory management and transportation routes.

Challenges in Developing and Owning Logistics Hubs

Despite their benefits, logistics hubs come with challenges. One major issue is the high upfront investment required to purchase and develop these facilities. Businesses must balance long-term gains with initial capital requirements.

Another challenge is location dependency. A logistics hub’s success depends heavily on its location. Poorly located hubs can lead to higher transportation costs and reduced competitiveness. Additionally, hubs must continually adapt to technological advancements and sustainability standards to remain efficient and compliant.

Future of Logistics Hubs

The future of logistics hubs will be shaped by sustainability, automation, and digitalization. Green building practices, renewable energy integration, and electric vehicle infrastructure will become standard features. Logistics hubs will also adopt more AI-driven solutions, transforming them into smart facilities capable of self-optimizing operations.

Furthermore, the rise of urbanization and e-commerce will drive demand for smaller, decentralized hubs located closer to city centers. These urban logistics hubs will play a critical role in meeting consumer expectations for ultra-fast deliveries.

Frequently Asked Questions

Q1. What is the difference between a logistics hub and a warehouse?

A warehouse primarily stores goods, while a logistics hub serves as a multi-functional facility that handles storage, sorting, distribution, and transportation. Logistics hubs are active nodes in supply chains, whereas warehouses often play a passive role.

Q2. Why invest in logistics hubs for sale instead of renting?

Owning logistics hubs provides long-term cost savings, customization options, and investment value. Businesses gain full control over their operations while building equity in a high-demand asset.

Q3. How does technology impact logistics hubs?

Technology improves efficiency, visibility, and accuracy in logistics hubs. Tools such as automation, AI, and IoT allow businesses to optimize inventory, reduce labor costs, and enhance real-time monitoring across supply chains.