Industrial Smart Warehouses Complete Guide with Benefits and Real-World Use Cases

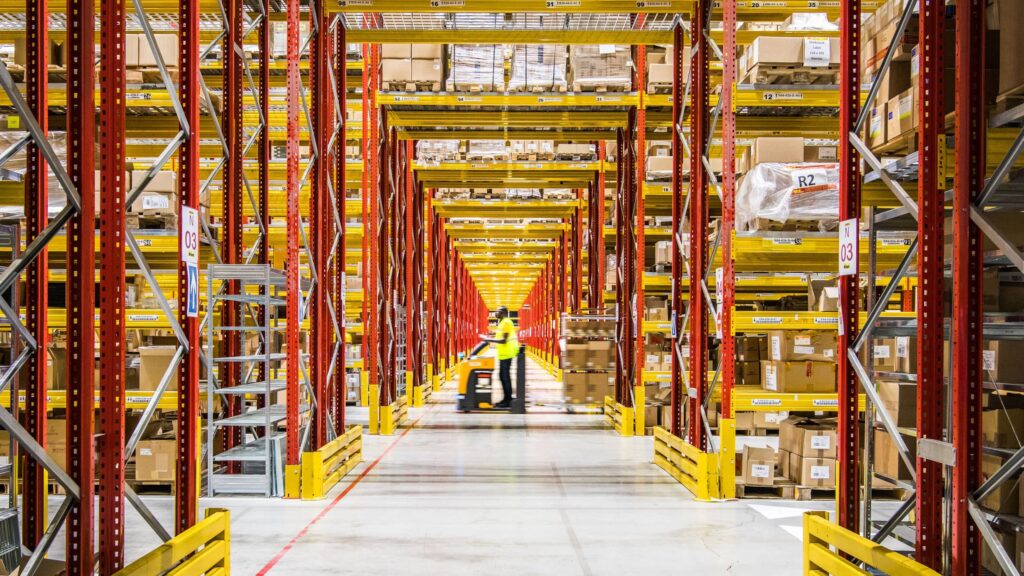

The term industrial smart warehouses refers to large-scale storage and distribution facilities enhanced with advanced technologies such as automation, artificial intelligence (AI), Internet of Things (IoT), and robotics. Unlike traditional warehouses, smart warehouses streamline logistics, improve efficiency, and reduce human errors.

These facilities are becoming critical to modern supply chains. The growth of e-commerce, global trade, and customer expectations for faster delivery have driven companies to adopt intelligent warehouse solutions. Businesses now rely on smart warehouses not only to store goods but also to optimize every step of inventory management and distribution.

Core Features of Industrial Smart Warehouses

Industrial smart warehouses integrate technology with infrastructure to enable efficient and data-driven operations. Key features include automated inventory tracking, robotic picking systems, AI-driven demand forecasting, and real-time monitoring of goods.

Another significant feature is connectivity. Smart warehouses use IoT devices and sensors to link storage systems, conveyors, and logistics platforms. This allows real-time updates across the supply chain and ensures that companies can respond to changes in demand, delays, or disruptions more effectively.

How Technology Shapes Smart Warehousing

Automation and digital systems are at the heart of smart warehouse operations. Warehouse Management Systems (WMS) provide a centralized digital platform where inventory levels, shipping schedules, and order fulfillment can be monitored. AI and machine learning algorithms analyze patterns, allowing warehouses to predict peak demand and allocate resources accordingly.

Robotics adds another layer of efficiency. Automated Guided Vehicles (AGVs) and robotic arms can move products from storage to shipping areas without manual handling, reducing errors and labor costs. Together, these technologies create a warehouse ecosystem that operates faster, smarter, and more reliably than traditional methods.

Real-World Examples of Industrial Smart Warehouses

1. Amazon Robotics-Powered Warehouses

Amazon has pioneered smart warehousing with robotics. Their facilities use robotic shelves and AGVs that bring inventory directly to human workers. This reduces the time needed for order picking and significantly boosts fulfillment speed.

The relevance of this example lies in scalability. Amazon operates some of the largest smart warehouses in the world, demonstrating how automation can handle millions of daily transactions while maintaining accuracy and efficiency.

2. DHL Smart Warehouses with IoT Integration

DHL has implemented IoT-enabled smart warehouses across Europe and Asia. These warehouses use sensors to track packages, monitor temperature-sensitive goods, and ensure security across all storage areas.

This example is crucial because it shows how IoT enhances visibility across the supply chain. Customers and managers can track shipments in real time, which improves trust, reduces losses, and ensures quality control for sensitive goods like pharmaceuticals or perishables.

3. Alibaba’s Cainiao Smart Logistics Network

Alibaba’s Cainiao warehouses are equipped with AI-driven sorting systems, autonomous vehicles, and smart delivery scheduling. These systems allow the company to handle large volumes during peak shopping seasons such as Singles’ Day, where millions of orders are fulfilled within hours.

The relevance here is adaptability. Cainiao’s smart warehouses prove that intelligent infrastructure can respond effectively to sudden surges in demand without compromising service quality.

4. Walmart’s Automated Distribution Centers

Walmart has invested in smart warehouses that combine robotics, AI, and big data analytics. Automated systems handle repetitive tasks, while AI predicts inventory needs to ensure shelves remain stocked.

This example highlights efficiency in retail logistics. Walmart’s approach reduces stockouts, improves customer satisfaction, and streamlines distribution across its vast store network.

Benefits of Industrial Smart Warehouses

Industrial smart warehouses provide multiple benefits that extend beyond simple storage:

-

Operational Efficiency: Automation minimizes human error and speeds up processes such as picking, packing, and shipping.

-

Cost Reduction: Robotics and AI reduce labor costs and optimize space usage, cutting long-term operational expenses.

-

Real-Time Data Insights: IoT and WMS systems provide live updates on stock levels, delivery timelines, and performance.

-

Scalability: Smart systems allow warehouses to expand operations quickly during peak seasons.

-

Sustainability: Many smart warehouses use energy-efficient systems and reduce waste through optimized inventory management.

These benefits make smart warehouses an essential component of future-ready supply chains.

Practical Use Cases of Industrial Smart Warehouses

Meeting E-Commerce Demands

E-commerce companies use smart warehouses to manage rapid order fulfillment and reduce delivery times. Automation ensures orders are picked and packed within minutes, meeting customer expectations for same-day or next-day shipping.

Managing Perishable Goods

For industries such as food or pharmaceuticals, smart warehouses maintain strict temperature controls and monitor conditions in real time. This prevents spoilage and ensures compliance with health regulations.

Handling High Seasonal Demand

During peak shopping seasons, smart warehouses can scale up operations without requiring large increases in manpower. AI systems predict demand, while robotics handles increased order volumes efficiently.

Improving Global Supply Chain Integration

Companies with international operations use smart warehouses to manage complex logistics. Real-time tracking and predictive analytics ensure that products move seamlessly across borders and reduce the risk of delays.

Future Outlook of Smart Warehousing

The future of industrial smart warehouses is shaped by AI-driven automation, autonomous vehicles, and sustainable energy solutions. Emerging technologies like 5G connectivity will allow even faster data transmission, enhancing IoT systems in warehouses.

Blockchain is also expected to integrate with warehouse systems, providing secure and transparent supply chain records. These advancements will further increase trust, reduce fraud, and optimize global trade logistics.

Frequently Asked Questions

Q1. What is an industrial smart warehouse?

An industrial smart warehouse is a technology-driven storage and distribution facility that uses automation, robotics, IoT, and AI to optimize inventory management and logistics.

Q2. How do smart warehouses differ from traditional warehouses?

Smart warehouses rely on digital systems and automation to manage inventory and operations efficiently, whereas traditional warehouses depend heavily on manual labor.

Q3. Which industries benefit most from smart warehouses?

E-commerce, retail, food, pharmaceuticals, and logistics companies gain the most, as these industries require fast, accurate, and reliable inventory handling and distribution.